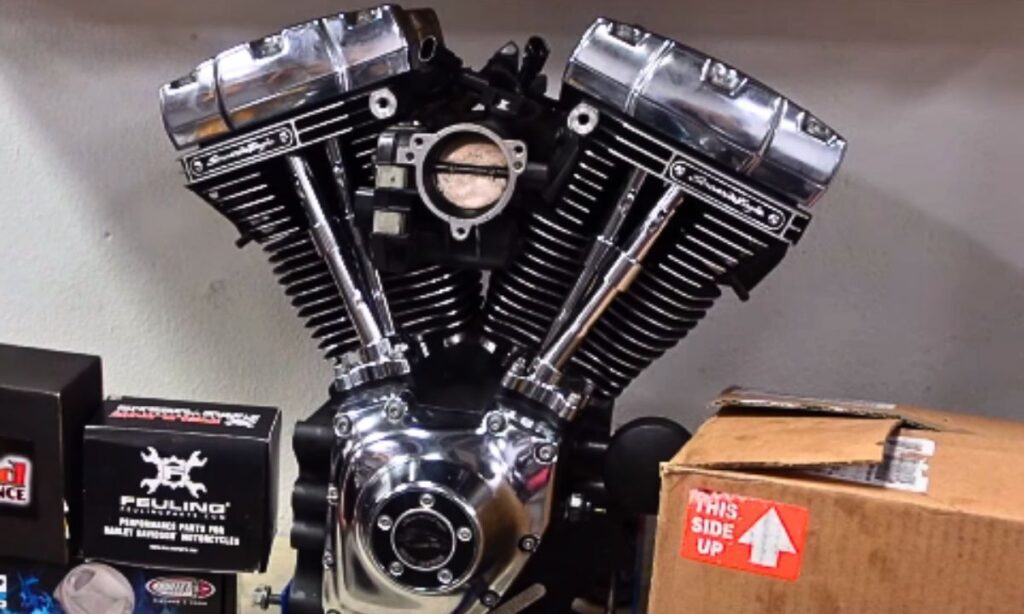

The Harley Davidson 114 engine, known for its robust power and superior performance, has been a staple in the Harley touring models.

However, like any mechanical component, it has been subject to a number of common issues that riders should be aware of.

In this article, we will explore these problems, providing insights into their causes and potential solutions for Harley enthusiasts.

Harley 114 Engine Problems

These problems largely revolve around heat management, excessive noise, and oil consumption.

The engine’s propensity to run hot, especially in traffic and during summer, leads to performance degradation over time.

Many users have reported ticking or knocking sounds, indicative of potential mechanical issues.

1. Wet Sumping

This phenomenon occurs when engine oil, instead of returning to the oil tank, accumulates in the crankcase or the gearcase.

While the engine is operational, the oil pump’s function is to distribute oil to lubricate the engine’s parts and then return it back to the tank.

However, if the bike remains idle for extended periods, gravity pulls the oil into the lower parts of the engine, leading to wet sumping.

Symptoms of wet sumping can be an overfilled crankcase, oil leakage, and smoke blowing out of the exhaust.

Moreover, it may lead to reduced engine performance or even severe engine damage.

To fix the wet sumping issue, try to ride your motorcycle regularly and avoid leaving it unused for long periods.

Replacing the check valve or oil pump can also help rectify this issue.

2. Vibration

One of the most common problems experienced by riders is excessive vibration especially at high RPMs. This issue affects the overall riding experience and has been a cause of concern for many.

The vibration is often most noticeable at high speeds, causing discomfort and reducing the bike’s handling.

Some riders have reported a feeling of ‘looseness’ in the bike parts, indicating a possible issue with the bike’s balancing or alignment.

While minor vibrations are a characteristic feature of any motorcycle, extreme or constant vibration can signal underlying mechanical issues that need immediate attention.

3. Excessive Noise

One common issue associated with 114, is excessive noise, often originating from the valve train or camshaft.

The noise can be described as a loud ticking or tapping sound, which becomes more pronounced under acceleration.

This issue can be due to the high valve train mass, which is amplified by increased engine speeds.

While some degree of mechanical noise is normal, excessive noise could indicate a pending or existing mechanical issue.

A thorough inspection can help to identify the exact source. This includes checking the pushrods for alignment, inspecting the rocker arms for excessive wear, and ensuring the lifters are functioning correctly.

Excessive noise could also stem from insufficient lubrication, so it’s crucial to use quality engine oil and maintain consistent oil changes.

In some cases, it may be necessary to replace the camshaft or other components of the valve train.

If the noise persists despite these steps, it’s essential to seek professional help.

4. More Oil Consumption

The engine, although known for its power and performance, consumes more oil than expected under certain conditions.

Aggressive driving can cause the engine to consume more oil. Frequent hard acceleration puts additional stress on the engine, causing it to burn more oil.

Riding your bike at high speeds over extended periods can also increase oil consumption.

The quality and type of oil used can significantly affect oil consumption. Using low-quality oil or oil not intended for high-performance engines can result in faster oil degradation and increased oil consumption.

Mechanical issues such as worn piston rings, valve seals, or even oil leaks can lead to excessive oil use.

To reduce oil consumption, adhere to a moderate driving style and use high-quality motor oil intended for high-performance engines.

If oil consumption seems abnormally high despite riding gently and using high-quality oil, it may be time for a mechanic to inspect the engine for possible mechanical issues.

5. Crankshaft Issues

The crankshaft, a critical component of Harley’s engine, is responsible for converting the linear motion of the pistons into rotational motion, which powers the bike.

The most reported issue related to the crankshaft is its propensity to slip out of alignment, often referred to as a ‘twisted crank.’

This can be attributed to the high torque output of the engine and the resultant stress exerted on the crankshaft.

Symptoms of this issue may include abnormal vibrations, decreased performance, and unusual noises from the engine.

To rectify this issue, it is advisable to take your motorcycle to a certified mechanic.

The mechanic will typically take the bike apart to correct the alignment and may even need to replace the crankshaft if it’s severely twisted.

6. Clutch Issue

This problem, often termed the ‘clutch issue,’ manifests in the form of a slipping clutch.

When a clutch slips, the motorcycle’s engine revs increase, but the speed does not, causing a noticeable lack of acceleration.

This is often the result of excessive wear on the clutch plates, incorrect clutch cable adjustment, or improper lubrication.

To resolve this problem, start by checking the adjustment of the clutch cable.

If it’s too tight, it can cause the clutch to slip. To correct this, adjust the cable to have a little free play.

Next, examine the clutch plates for wear. If they’re worn out, they’ll need to be replaced.

When you have replaced them, ensure to choose high-quality plates suitable for your Harley’s 114 engine.

Lastly, make sure the clutch is properly lubricated. Regular maintenance and oil changes can prevent many clutch issues.

7. Starting Issue

The starting problem could result as a hard start or, in some cases, the engine refusing to start entirely.

This issue can arise from a depleted battery, a defective starter motor, problems with the ignition switch, or even an ineffective fuel system.

To troubleshoot this issue, start by checking the battery. Ensure it is adequately charged and the connections are clean and tight.

If the battery is beyond its useful life, consider replacing it with a new one.

The starter motor is another key area to inspect. If it’s faulty, the engine will not turn over as required. Replacing or repairing the starter motor solves this problem in most cases.

Next, inspect the ignition switch and the fuel system. If the ignition switch is broken or worn out, the motorcycle might not start.

The fuel system, including the fuel pump and the fuel injectors, must also be functioning properly for the engine to start.

8. Loose Pistons

The Harley 114, while offering impressive power and torque, has been reported to occasionally face issues with loose pistons.

This is a significant concern as it can lead to a myriad of engine problems, potentially including engine failure.

Loose pistons occur when the piston-to-wall clearance is more than the manufacturer’s specifications.

This could be due to poor manufacturing, wear and tear, or improper installation.

The symptoms of loose pistons can be excessive noise, lack of power, poor fuel economy, and increased oil consumption.

To rectify this issue, here is a basic guide:

- Begin by safely removing the engine from the bike, following the manufacturer’s instructions.

- Disassemble the engine, paying close attention to the arrangement of components for reassembly. Inspect each part for wear or damage.

- Check for abnormal wear or damage on the piston. If the piston is loose or shows signs of excessive wear, it likely needs to be replaced.

- Inspect the cylinder walls as well. If wear or scoring is found, the cylinder may need to be re-bored or replaced.

- Replace the defective pistons and/or cylinder as necessary, then reassemble the engine and reinstall it.

9. Low Cam Chain

One common problem that riders encounter is related to the low-cam chain tensioners.

These parts, essential for proper engine timing and synchronization, can exhibit wear and tear over time, leading to performance issues or even significant engine damage.

The cam chain tensioners are responsible for maintaining the right tension in the chain that connects the camshafts, ensuring they rotate at the correct speed relative to the crankshaft.

When these tensioners begin to degrade, they may not provide the necessary tension, leading to the chain becoming loose.

This situation can result in a noisy operation, reduced power output, and even severe internal engine damage if the chain slips or breaks.

Therefore, it’s crucial to routinely inspect and replace these parts as part of their regular maintenance schedule.

When replacing the cam chain tensioners, it is recommended to use only high-quality parts designed for your specific engine model.

The replacement process requires specialized tools and knowledge, and it’s often best left to a professional mechanic.

10. Unreliabiliable Radiator

The radiator, a critical component in cooling the engine, presents several issues impacting the bike’s performance.

These issues range from coolant leaks, leading to overheating, to blockages and rust, preventing the coolant from circulating effectively.

A common sign of radiator unreliability is a noticeable drop in engine performance, including overheating, especially during high-speed rides or in warmer climates.

In such situations, the radiator is unable to dissipate the heat generated by the engine efficiently.

Regular inspection for any coolant puddles under the parked bike can help identify leaks early.

On the other hand, a blocked radiator usually results from the accumulation of debris or rust inside the radiator.

To avoid these problems, regular maintenance, periodic coolant changes, radiator flushes, and inspections for leaks or damage are crucial.

Radiator guards can also be used to protect against debris and external damage. If issues persist, it might be necessary to replace the radiator entirely.

11. Miscalculated Acceleration

One of the significant issues that users have reported with the Harley 114 is a miscalculated acceleration.

This is often perceived as an unexpected surge in speed or power during gear changes, posing potential safety risks.

The root cause could be a variety of factors, including throttle response inconsistencies, gearbox malfunctions, or an imbalance in the fuel-air mixture.

To troubleshoot this issue, start by checking the throttle response. Ensure it is smooth and consistent throughout the rev range.

Next, inspect the gearbox for any signs of wear or damage. If there is a mechanical issue, this may require professional attention.

Another possible cause can be an incorrect fuel-air mixture. If the engine is running lean (too much air and not enough fuel), this can lead to erratic performance.

Talha Younas, the brains behind the influential motorcycle-focused website, TwoWheller.com, is a dedicated and passionate advocate for biking culture. Born and raised in a family of motorcycle enthusiasts, his love for two-wheeled transportation was ignited at an early age. His commitment to providing in-depth reviews and helpful tips for riders has established him as a respected figure in the motorcycle community.