As a long-time motorcycle enthusiast, I’ve ridden many Harley motorcycle engines. Mostly, it’s a great experience because Harley makes strong bikes and engines.

But even the best things can have small problems sometimes. One of the problems I found is with the Harley 117 engine. Even a very strong engine can have a few issues.

In this article, we will dive into the problems that the Harley 117 engine owners faced over time.

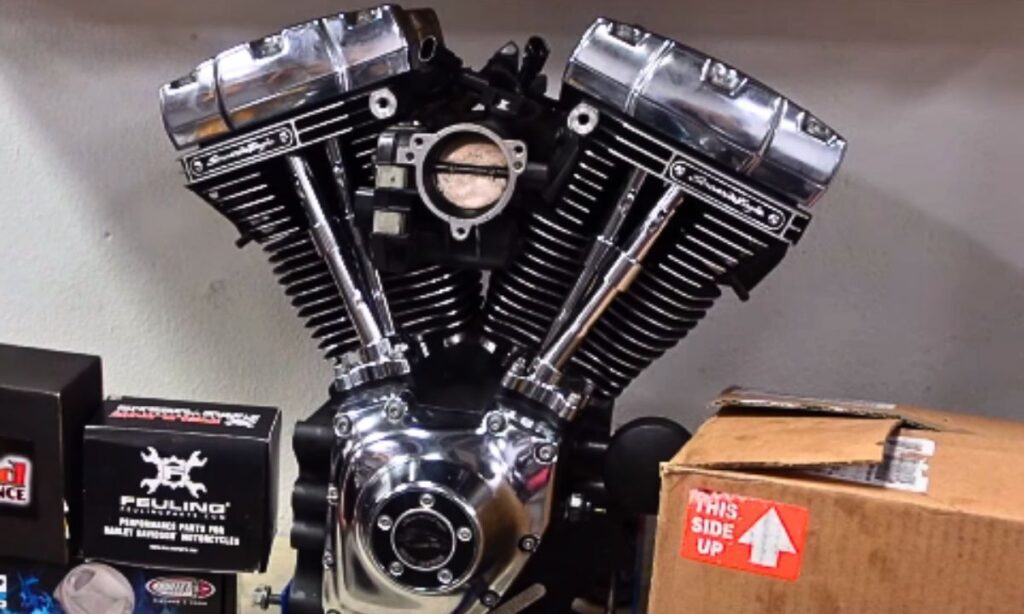

Harley 117 Engine Problems

Some riders have reported overheating problems, particularly during extended rides or in high-temperature conditions.

Others have experienced unusual noises indicative of potential mechanical problems, including clicking or knocking sounds.

However, there have also been instances of oil leakage, significantly impacting the engine’s performance and requiring immediate attention.

1. Excessive Oil Consumption

Excessive oil consumption is a common issue seen, typically a significant decrease in the oil level between regular service intervals.

This problem could stem from various factors like worn-out piston rings, valve guide seals, or even excessive engine heat.

I. Piston Rings

Worn-out piston rings can cause oil to leak into the combustion chamber, leading to excessive oil consumption.

To diagnose this, you can perform a compression test. If the compression is low, it’s a clear sign that the piston rings might be worn out.

II. Valve Guide Seals

Valve guide seals help to prevent oil from the cylinder head valve guides from dripping into the engine cylinders.

If these seals become worn or damaged, they can allow oil to leak into the combustion chambers, resulting in excessive oil consumption.

A bluish or grayish exhaust smoke is a common sign of faulty valve guide seals, especially during startup.

III. Engine Heat

Excessive engine heat can also lead to increased oil consumption. The extreme temperatures can cause oil to thin and vaporize, which then gets burnt off in the combustion process.

Regularly inspecting and maintaining the cooling system can help manage engine heat and reduce oil consumption.

2. Oil Leakes

Oil leaks can occur due to bad seals, broken gaskets, or excessive engine pressure. Regular inspection and maintenance can significantly reduce the occurrence of oil leaks.

To troubleshoot this issue, start by identifying the source of the leak. Look for oil stains or drops on the ground beneath the engine bay.

Also, check if the oil level in your bike has significantly reduced over a short period. Next, if the leak is due to bad seals or broken gaskets, these components need to be replaced.

This involves draining the old oil, removing the faulty seal or gasket, replacing it with a new one, and then refilling it with fresh oil.

If the oil leak is due to excessive engine pressure, the ventilation system needs to be checked. The crankcase ventilation system helps to maintain the correct pressure balance inside the engine.

If it is blocked or not functioning correctly, it can cause excessive pressure build-up, leading to leaks.

3. Overheating

Overheating is a common issue owners; it can lead to severe complications if not addressed promptly.

This problem typically arises due to the air-cooled design of the engine, which struggles in areas with high ambient temperatures or slow-moving traffic.

The signs of overheating may be a decrease in performance, knocking noise from the engine, or even smoke in severe cases.

To prevent overheating, ensure the engine is properly maintained and regularly serviced.

Using synthetic oil can enhance heat dissipation while installing a higher-capacity oil cooler or fan can further aid in cooling the engine.

If your Harley 117 engine overheats, it is crucial to not shut it down immediately as it can cause heat soak.

Instead, let it idle and cool down gradually. Regularly monitoring the engine temperature and taking preventive measures can significantly reduce the risk of overheating.

4. Camshaft Issues

This problem typically arises from a lack of adequate oiling, which can be due to multiple reasons, including a faulty oil pump.

A failing camshaft in a 117 engine is often indicated by a knocking or ticking noise coming from the engine.

To address this issue, start by verifying the oil pressure and ensuring it is at the right level.

If the oil pressure is in the normal range but the problem persists, it may be time to inspect the camshaft itself.

For this, disassemble the engine and inspect the camshaft for signs of wear or damage. Look out for uneven wear patterns, pitted surfaces, or damaged lobes.

If you do find damage on the camshaft, it will need to be replaced. Remove the old camshaft carefully, making sure not to damage any surrounding parts.

Then, install the new camshaft according to the manufacturer’s instructions.

Remember to apply a liberal amount of engine assembly lube on the lobes and bearing surfaces of the new camshaft before installing it.

Once the new camshaft is installed, reassemble the engine and ensure that the oil flow to the camshaft is adequate.

Start the engine and allow it to idle for a few minutes to allow the new camshaft to ‘break in.’

Monitor the engine closely during this period to make sure there are no unusual sounds or vibrations.

5. Unusual Noise

Unusual noise is reported by various riders all over the world; it can be a clear sign of mechanical issues.

This noise could be due to various causes, including problems with the rocker arms, camshaft, lifters, or even the crankshaft.

It’s crucial to not ignore these sounds as they may lead to serious engine damage.

If you hear ticking or clicking noises, especially during startup or idle, this might indicate a problem with the valve train components.

These noises can be caused by worn-out or damaged parts such as the rocker arms and lifters.

A knocking or pinging noise is commonly associated with incorrect ignition timing or fuel issues.

Advanced ignition timing or low-quality fuel can cause a pre-ignition or detonation, creating these sounds.

If you hear a rattling sound, then it could indicate a problem with the drive belt, drive chain, or even the camshaft.

To address these issues, you’re advised to get a complete engine check-up by a certified mechanic.

6. Hard Starting

Hard starting often indicates an underlying issue with the ignition system, fuel system, or potentially the engine’s compression.

Here are some of the issues that can cause this problem:

I. Ignition System

Check your spark plugs and ignition wires. The spark plugs might be worn out, or the gap between the spark plug electrodes could be incorrect. The ignition wires might be damaged or loose.

II. Fuel System

Inspect the fuel pump, the fuel filter, and the fuel injectors. These components might be blocked or malfunctioning, preventing the right amount of fuel from reaching the engine.

III. Engine Compression

Low engine compression can also cause hard starting. This could be due to worn piston rings, damaged cylinder walls, or leaky valves.

7. Vibration

One common issue experienced by owners is excessive vibration especially at higher RPMs.

This can come across as a noticeable, and often uncomfortable, shaking felt through the seat, handlebars, and foot pegs while riding.

It could be due to the inherent design of the V-twin engine, which is prone to vibration.

The heavy pistons and connecting rods can create additional vibration, especially at high RPMs. Incorrect alignment or balancing of the engine’s components can exacerbate the problem.

To mitigate these vibrations, you can look into a few solutions. Start by checking if your engine mounts are in good condition; worn out or damaged mounts can increase vibrations.

If the problem persists, consider seeking a professional balance job for your engine’s rotating assembly.

8. Transmission Issue

The 117 is known for its power and performance and may sometimes face transmission issues that can affect the bike’s overall efficiency.

One of the common issues is difficulty in shifting gears, which could be caused by a worn-out clutch or poorly adjusted shift linkage.

The clutch is a crucial component that controls the power flow between the engine and the transmission.

If you notice any difficulty or delay while shifting gears, it could be a sign of clutch wear.

In such cases, it’s advisable to replace the clutch. Always use a premium-quality clutch to ensure durability and smooth gear shifting.

Poorly adjusted shift linkage can also lead to transmission issues. The shift linkage should be adjusted so that the gear shift foot lever is 1/2 to 3/4 of an inch above the footrest.

You can adjust it by loosening the lock nuts at each end of the shift rod and turning the rod until the lever is at the right height. Remember to tighten the lock nuts properly once you’re done.

Talha Younas, the brains behind the influential motorcycle-focused website, TwoWheller.com, is a dedicated and passionate advocate for biking culture. Born and raised in a family of motorcycle enthusiasts, his love for two-wheeled transportation was ignited at an early age. His commitment to providing in-depth reviews and helpful tips for riders has established him as a respected figure in the motorcycle community.