As a motorcycle enthusiast, I’ve encountered a myriad of engines, each with its own quirks and special features.

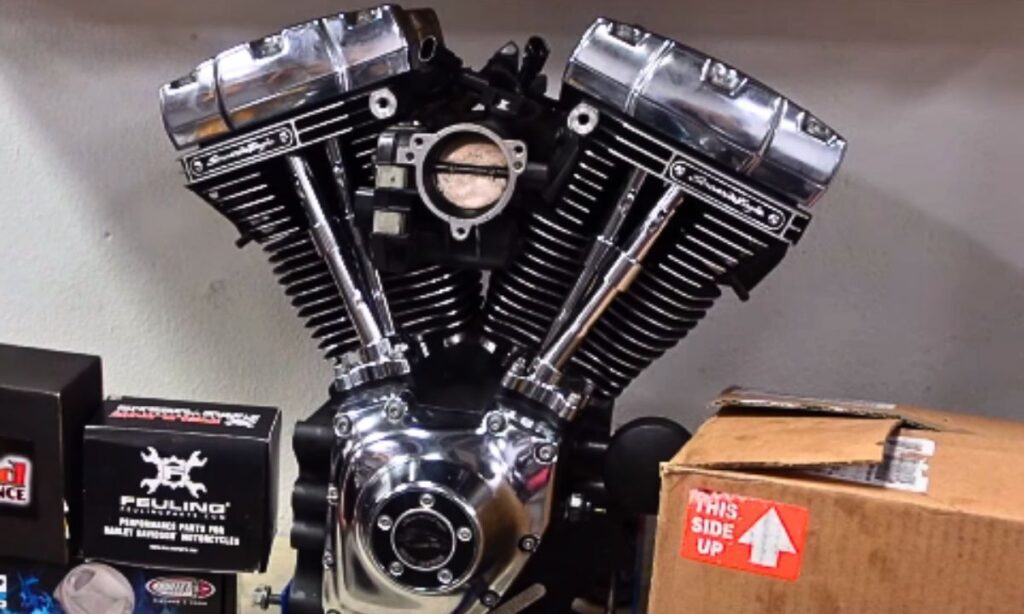

Among them, the Harley Davidson 103 engine stands out, synonymous with the renowned roar and powerful performance that Harley Davidson bikes are celebrated for.

But, as with all mechanical things, it’s not without its problems. I’ve experienced first-hand the challenges that can accompany this engine.

In this article, we will explore the problems that I faced with the Harley 103 engine over time.

Harley Davidson 103 Engine Problems

Users commonly report problems such as excessive heat generation, which lead to rider discomfort and potentially impact the engine’s longevity.

Some riders also note unanticipated oil leaks, an issue that can be distressing and needs swift rectification to prevent further complications.

There’s the concern of the dreaded ‘Harley Wobble,’ a stability issue at high speeds that can create a potentially dangerous riding scenario.

1. Overheating

This problem often arises due to inadequate cooling and can lead to significant damage if not addressed promptly.

Overheating can be identified by such as a decrease in engine performance, unusual engine noise, or an engine warning light appearing on the dashboard.

The motorcycle might also feel hotter than usual when in operation, or you may notice a burning smell.

To prevent overheating, ensure your Harley is adequately serviced and maintained. Regularly check the coolant levels and ensure the cooling system is functioning effectively.

Replace old or damaged coolant hoses, and regularly clean the radiator to remove any debris that might impair airflow.

In case of consistent overheating, it’s advisable to have a professional mechanic inspect the engine.

2. Crankshaft Issue

This integral engine component translates linear piston motion into rotational motion, which ultimately propels the motorcycle.

A common problem, particularly with higher mileage engines, is the wearing down of the crankshaft bearings.

This wear and tear can lead to a loud knocking or banging noise while the engine is running. To address this issue, firstly, assess if there’s a significant lateral movement in the crankshaft.

Any play more than the manufacturer’s recommended tolerance could be indicative of a worn bearing.

If this is the case, the crankshaft would need to be disassembled to replace the worn-out bearings.

Keep in mind that this is a complex task that requires advanced mechanical knowledge, as it involves dismantling a significant portion of the engine.

3. Oil Leakes

This issue can stem from a variety of reasons, but the most common ones are faulty gaskets, worn-out seals, or damage to the oil pan or its plug.

The gaskets are typically found between two metal surfaces in the engine to prevent leakage. Over time, due to heat and pressure, these gaskets can wear out, leading to oil leakage.

Similarly, the seals around the rotating parts can get worn out, causing oil to seep out. Any damage to the oil pan or its plug can also lead to an oil leak.

To avoid the oil leaks, ensure that the gaskets are the issue. If they are behind this issue, then the solution is to replace them.

Make sure to inspect gaskets regularly and replace them once signs of wear are visible.

If you suspect that the seals are worn out, you may need to seek professional help, as replacing them could involve dismantling parts of the engine.

If the oil pan or its plug is damaged, replacement might be the best option rather than repairing it.

It’s crucial to ensure that the replacement part is compatible with your Harley Davidson 103 engine to prevent future leaks.

4. Excessive Noise

One common issue reported with the Harley 103 is excessive noise, particularly a loud ticking noise.

This is typically caused by the hydraulic lifters, which are a vital part of the valve train. These lifters use oil pressure to maintain proper clearance between the cam lobe and the push rod.

However, when they fail or wear out, the clearance becomes too great and results in a ticking noise.

This noise tends to increase in volume with the engine’s RPM, making it more noticeable at higher speeds.

In order to address this issue, the lifters should be inspected and replaced if necessary. To inspect the lifters, you will need to remove the push rods and then extract the lifters from their bores.

Look for excessive wear or damage on the bottom of the lifters. If they appear worn or damaged, they will need to be replaced.

It’s recommended to replace all the lifters at the same time to ensure the engine performs uniformly.

When replacing lifters, it’s also a good idea to change the oil and filter to remove any potential contaminants that may have caused the lifter’s failure.

After completing these steps, you should notice a significant reduction in the engine noise.

5. Vibration

Although a certain level of vibration is normal with any motorcycle engine, the severity of the vibration in the 103 engine can sometimes be a cause for concern.

Excessive vibration can lead to a less comfortable ride and potentially damage to the motorcycle over time.

It’s caused by a combination of factors such as manufacturing tolerances, engine mount design, and driving habits.

Sometimes, the vibrations may even originate from the crankshaft if it becomes unbalanced. The first step in addressing this issue is to identify the source of the vibration.

This can be done by a professional mechanic or an experienced rider who knows what to look for.

If you’re experiencing vibrations when the motorcycle is idling, this could indicate that the engine mounts need to be replaced.

On the other hand, if the vibrations occur at high speeds, this could be a sign of an issue with the balance of the crankshaft. In this case, the crankshaft may need to be rebalanced or replaced.

6. Starting Problem

Every engine has been known to encounter starting issues or hard starting, which can be quite frustrating for riders.

This problem usually manifests itself as the engine struggling to turn over or requiring multiple attempts to start.

The issue could be due to several factors:

I. Battery Problems

A weak or aging battery might not have the power needed to crank the engine. Therefore, it’s essential to regularly inspect the battery and replace it if necessary.

II. Spark Plug Issues

If the spark plugs are damaged or worn out, they may not ignite the air-fuel mixture in the engine’s cylinders properly, leading to starting issues.

Checking and replacing spark plugs should be part of your routine maintenance.

III. Fuel System Problem

Issues in the fuel system, such as clogged fuel injectors or a malfunctioning fuel pump, can prevent the engine from getting the fuel it needs to start.

IV. Starter Motor Failure

If the starter motor is faulty, it will not turn the engine over adequately. If you hear a clicking sound when trying to start the bike, this might be your issue.

7. High Compression Ratio

The compression ratio is the measure of the cylinder’s volume from its largest capacity to its smallest capacity.

A high compression ratio implies that the engine is squeezing the air-fuel mixture in its cylinder harder, leading to a higher temperature and pressure.

A high compression ratio can cause the motorcycle to run hotter than usual, leading to overheating issues.

It can also result in detonation or pre-ignition, which is when the air-fuel mixture in the cylinder ignites too soon. This can potentially cause serious damage to the engine.

The high compression ratio can be due to modifications to the engine heads, improper tuning, or even the use of low-octane fuel.

Therefore, it’s crucial to take necessary precautions and maintenance steps to avoid this problem.

8. Tight Packaging

The motor is packed incredibly tightly into the frame of the bike, leaving little room for essential components to breathe.

This compact design can result in the bike running hot, especially during long rides or in warm climates.

To mitigate this issue, it’s essential to provide adequate ventilation. Regular check-ups and maintenance to ensure that the engine is functioning properly.

Installing a high-performance fan or oil cooler can also help disperse heat more efficiently. The tight packaging may make it difficult to repair or replace the engine components.

When working on your bike, ensure you have the right tools for the job – a service manual for your specific model can be a valuable resource.

Key Features Of Harley Davidson 103 Engine

The Harley Davidson 103 engine is renowned for its robustness and unmatched performance.

This high-torque powertrain, boasting 1690 cubic centimeters of displacement, gives you the thrill of exceptional on-road power.

Its air-cooled Twin Cam design not only offers a smooth ride but also ensures reliability and longevity.

Here are some of the key features of the Harley 103 engine:

1. Improved Braking System

Harley Davidson’s 103 Engine features an advanced braking system that significantly enhances the safety and control of the motorcycle.

This system, known as the Reflex Defensive Rider System (RDRS), integrates electronically linked brakes for optimum braking in various road conditions.

RDRS’s primary function is to balance the amount of brake pressure applied to the front and rear wheels, preventing wheel lockup.

When the system detects excessive brake pressure, it automatically reduces it, allowing for smoother deceleration and preventing skidding.

This technology is particularly useful when riding on slippery or uneven surfaces. However, this system includes a Cornering Enhanced Antilock Brake System (C-ABS).

This feature adjusts brake pressure based on the lean angle of the motorcycle, offering greater control and stability while navigating corners.

The braking system is easy to operate. Once the engine is started, RDRS is automatically activated.

The key to effectively utilizing this system is understanding its functions and limitations. While it significantly improves safety, it does not eliminate the need for safe riding practices.

By offering a high level of control and safety, the advanced braking system in the Harley Davidson 103 engine sets a new standard in motorcycle technology.

2. Improved Push Butter Seals

These seals play a crucial role in maintaining the efficiency and performance of the engine.

They are specially designed to prevent oil leaks from the push rod tubes, ensuring that the engine operates smoothly and efficiently.

Built with high-quality materials, these seals exhibit superior resistance to heat and wear, thereby enhancing their longevity.

The installation process of the Improved Push Rod Seals is relatively straightforward.

First, it involves removing the old seals. This can be done by loosening the push rod tubes and pulling out the old seals.

Then, the new seals are installed in the reverse order of removal. It is essential to ensure that the seals are seated properly in their grooves to prevent oil leakage.

It’s recommended to lubricate the seals before installation to reduce friction and facilitate proper seating.

3. Advanced Injection System

The 103 possesses an advanced fuel injection system, enhancing its performance and fuel efficiency.

This system replaces the traditional carburetor, ensuring optimal fuel-air mixing and precise fuel delivery.

It operates on a closed-loop system that continually adjusts fuel delivery to match riding conditions, in turn improving throttle response and overall engine performance.

The system includes an Electronic Control Module (ECM) that collects data from a multitude of sensors located throughout the engine.

These sensors measure parameters like air intake temperature, throttle position, and engine speed.

The ECM processes with this data adjust the fuel-to-air ratio, ensuring optimal combustion and reducing emissions.

4. Reinforced Clutch

It’s built from tough materials to withstand regular use, making sure the engine’s power is smoothly passed on to the wheels.

The parts of the clutch are improved, and the springs are stronger, giving you a smooth and controlled ride.

To keep the clutch working well, it’s important to check it regularly for any signs of wear and keep an eye on the clutch fluid levels.

5. Electronic Alarm

This engine is equipped with an advanced electronic alarm system, ensuring maximum security for your beloved motorcycle.

This system uses a hands-free fob that communicates directly with the motorcycle.

When the fob is within the range of the bike, the system automatically disarms, allowing you to start your ride without any hassle.

In case you move away from the bike, the system arms itself, effectively preventing any unauthorized access.

If an attempt is made to move or tamper with the bike in this state, the alarm system triggers a loud siren, drawing attention and deterring potential thieves.

To further enhance security, the system also includes an ignition cut-off feature that prevents the engine from starting when the alarm system is armed.

This effectively immobilizes the bike, making it nearly impossible for anyone to steal or tamper with it.

Moreover, the Harley Davidson 103 engine also comes equipped with a unique keyless ignition system, eliminating the need for traditional keys.

The system uses a code that is entered into the motorcycle’s electrical systems, allowing you to start your bike with just a push.

Tonmoy, the brains behind the influential motorcycle-focused website, TwoWheller.com, is a dedicated and passionate advocate for biking culture. Born and raised in a family of motorcycle enthusiasts, his love for two-wheeled transportation was ignited at an early age. His commitment to providing in-depth reviews and helpful tips for riders has established him as a respected figure in the motorcycle community.