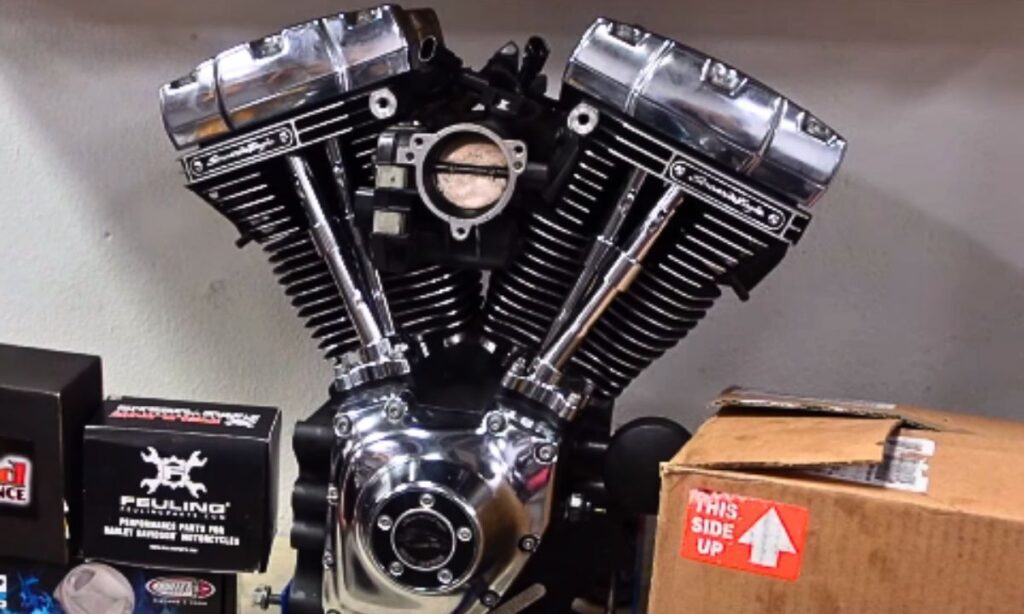

The Harley Davidson Evolution engine marked a new era of innovation and performance for the renowned motorcycle brand when it was introduced in 1984.

While the engine has earned a reputation for reliable performance and longevity, it is not without its share of issues.

In this article, we will explore some of the common problems associated with the Harley Davidson Evolution engine.

Harley Davidson Evolution Engine Problems

Despite its popularity and aesthetic appeal, several recurring issues have been reported by riders over the years.

Some of the most common problems are oil leaks, ineffective starter systems, overheating, and vibration, each of which significantly affects the performance of motorcycles.

Here are some common problems reported by most riders about the Evo engine.

1. Starting Issues

This problem usually results as the engine struggles to ignite or not start at all. The root cause of this issue often lies in the starter motor, a key component responsible for igniting the engine.

It may fail due to several reasons, such as wear and tear over time, poor maintenance, or a manufacturing defect.

If the starter motor is not working efficiently, it can’t generate enough power to start the engine.

To troubleshoot this issue, start by checking the battery’s condition and charge. If the battery is fine, turn your attention to the starter motor.

A faulty starter motor often makes a clicking or grinding noise. If you notice these sounds, the starter motor likely needs to be replaced.

Another issue could be a faulty ignition switch. To check this, try starting the motorcycle with the headlights on.

If the headlights dim significantly or go out when you attempt to start the engine, the ignition switch may be the culprit.

2. Low Oil Pressure

This issue can stem from a failing oil pump, blocked oil passages, or worn-out engine components.

Low oil pressure means that the engine isn’t getting the necessary lubrication to operate smoothly, leading to increased friction, overheating, and, in worst cases.

If you’re faced with low oil pressure, the first step you should take is to check the oil level in your motorcycle.

If the oil level is too low, it can cause the oil pump to draw in air, leading to a drop in oil pressure. To fix this, simply refill the oil to the required level.

If the oil level is adequate, the next possible culprit could be your oil pump. A malfunctioning oil pump may not be able to deliver oil effectively throughout the system.

In this scenario, replacing the oil pump is the most effective solution.

Lastly, there might be blockages in the oil passages due to accumulated dirt and debris or worn-out engine parts contributing to low oil pressure.

In such cases, a complete engine cleanup or component replacement might be necessary.

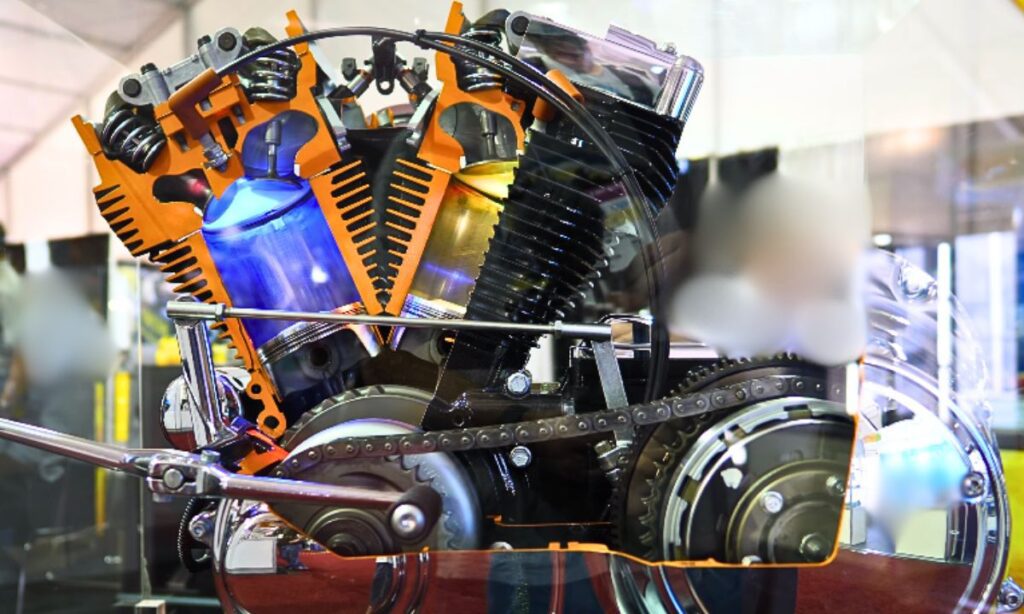

3. Cam Chain Tensioner

The cam chain tensioner is responsible for maintaining the correct tension in the cam chain, a crucial component that controls the engine’s timing.

However, in many engines, the cam chain tensioners, particularly made of nylon, have been known to wear out prematurely.

The small particles of nylon then circulate through the engine with the oil, potentially causing serious engine damage.

The main issue is that the tensioners are hidden deep within the engine and require significant disassembly to inspect or replace, making this problem hard to diagnose.

Upgrading to hydraulic tensioners or converting to gear drive are two common solutions that riders have used to mitigate this problem.

As a responsible rider, you should inspect the tensioners every 15,000 to 20,000 miles.

4. Engine Smoking

The problem is often indicative of oil seeping into the combustion chamber, burning alongside the fuel.

It could be due to worn-out piston rings, faulty head gaskets, excessive oil fill, or a compromised breather system.

Worn-out piston rings allow oil to creep into the combustion chamber during the compression stroke.

In case of faulty head gaskets, oil bypasses mixes with the coolant, leading to smoke emission.

Overfilling the engine with oil can also cause smoke as the excess oil is forced out of the engine, especially during high-speed rides.

The breather system’s failure can cause oil to be sucked back into the carburettor, which enters the combustion chamber and causes smoke.

5. Rough Idle Issue

This problem is characterized by an uneven, shaking or bouncing sensation when the motorcycle is idling.

The engine might seem to start smoothly but then begin to vibrate excessively, causing the whole bike to shake and making the ride uncomfortable.

It could be due to poor fuel quality or a clogged fuel injector, which prevents the fuel from flowing smoothly into the engine.

Another possibility could be a faulty spark plug or ignition coil that is not igniting the fuel-air mixture properly.

To diagnose and resolve the rough idle issue, you need to follow a systematic process.

Start with checking the fuel quality and ensure it’s not contaminated. If the fuel is fine, check the fuel injectors for any sign of clogging or damage.

Use a fuel injector cleaner if necessary. Next, examine the spark plugs and ignition coils for any sign of wear or damage.

Replace them if necessary. Regular maintenance and timely repair can help prevent this issue and ensure a smoother ride.

6. Vibration Issue

The vibration issue typically arises due to the two-cylinder design of the Evolution engine.

This V-twin configuration, while iconic in its aesthetic and sound, inherently produces significant vibration.

When these vibrations become excessive, they lead to far-reaching consequences, affecting ride quality, causing wear and tear on bike components, and reducing the overall longevity of the engine.

It could be due to an imbalance within the engine itself, such as misaligned components or inappropriate weight distribution.

Over time, these imbalances can exacerbate vibrations, leading to issues like loosened bolts, broken mounts, and even structural damage to the bike’s frame.

Early signs of the vibration problem may include an unusually harsh or rough ride, visible shaking at idle or when revving the engine, or an unusual increase in noise levels.

7. Bearing Failures

The inner cam bearing is a crucial component in the engine, ensuring the smooth and efficient operation of the camshaft.

Failure of the inner cam bearing can result in significant engine damage.

Typically, these failures are due to the high stress placed on the bearings from the action of the camshaft, combined with inadequate lubrication.

Symptoms of a failing inner cam bearing can include loss of power, unusual engine noise, or metal fragments in the engine oil.

To address this issue, regular inspection and maintenance of the inner cam bearings is crucial. High-quality replacement bearings designed

8. Bad Lifters

This component plays a vital role in maintaining the smooth operation of the engine.

When the lifters fail, it can lead to ticking noise from the engine, reduced performance, and, in severe cases, complete engine failure.

The inner cam’s bad lifters issue typically arises due to wear and tear or lack of maintenance.

Over time, the lifters can wear down, leading to excessive clearance, which in turn causes the ticking noise.

However, without regular oil changes and maintenance, debris can build up in the lifters, leading to failure.

It’s essential to diagnose the problem correctly. This can usually be done by listening for the characteristic ticking noise and by fully inspecting the lifters for signs of wear or debris.

If a problem is identified, the faulty lifters must be replaced. This is a skilled task, typically requiring the services of a professional mechanic.

9. Power Loss

Power loss is a critical issue where the engine gradually loses its capacity to generate the required power for optimal performance.

This is often indicated through symptoms such as the motorcycle’s inability to reach its top speed, inconsistent acceleration, or a notable decrease in fuel efficiency.

It could be due to clogged air filters, spark plug issues, carburettor problems, or fuel injector issues.

A clogged air filter can hinder the proper air-fuel mixture necessary for combustion, while a faulty spark plug can disrupt the ignition of the air-fuel mixture.

Similarly, issues with the carburettor can affect the air-fuel ratio, and problems with the fuel injectors can interrupt the delivery of fuel to the engine.

Addressing power loss issues involves a thorough inspection and troubleshooting process. Start by checking the air filter and replacing it if it is clogged or dirty.

Then, inspect the spark plugs for any signs of wear or damage and replace them if necessary.

If these do not resolve the issue, consider checking the carburettor or fuel injectors.

10. Overheating

Overheating is a common problem that plagues the Harley Evolution engines.

The intense heat generated by the engine during operation, can lead to severe damage and engine failure.

The overheating problem in these engines often results as a rise in engine temperature, which causes the engine to ‘seize up’ or stop working altogether.

This is often due to inadequate cooling or problems with the cooling system, such as a malfunctioning radiator, a broken coolant pump, or low coolant levels.

Addressing overheating is essential to prevent long-term damage. Start by checking the coolant levels and topping them up if necessary.

Then, inspect the radiator for any blockages or leaks which could cause the coolant not to circulate properly.

The coolant pump also needs to be checked to ensure it’s functioning correctly.

If all these are working properly and the engine is still overheating, it may be best to seek the help of a professional mechanic.

11. Tight Valve Clearance

This problem is characterized by the valve not fully closing, which restricts the flow of air and fuel into the engine and the expulsion of exhaust gases out of it.

Valve clearance refers to the small gap between the rocker arms and valve stem tips, which is essential for the proper functioning of an engine.

This gap allows the valves to cool, ensuring they don’t overheat and warp.

When this clearance is insufficient or tight, there is a risk of the valves remaining partially open even when they should be closed.

This issue can lead to several effects on engine performance, it can cause misfiring, loss of power, and poor fuel efficiency.

In severe cases, it can even lead to valve burning, a condition that necessitates expensive and time-consuming repairs.

To fix Tight Valve Clearance problems, you should adjust the valve lash to the manufacturer’s specifications.

This process typically involves removing the valve cover, checking the current valve clearance using a feeler gauge, and adjusting the rocker arms accordingly.

12. Engine Shuts Off

This problem generally occurs when the motorcycle is running at high speeds, leading to unexpected and abrupt stops in the middle of the ride.

A faulty ignition switch could be one of the potential culprits. If the switch is malfunctioning, it can lead to an intermittent power supply, causing the engine to shut off.

The problem can also stem from contaminated fuel or a clogged fuel filter. To solve this issue, the first step is to diagnose the cause. Replace the ignition switch if it’s faulty.

Regularly check your fuel quality and replace the fuel filter if it’s clogged. You may also need to clean the fuel lines and tank if contamination is suspected.

A complete tune-up of your motorcycle, including regular maintenance of the engine, can help keep this problem at bay.

13. Misfiring

This phenomenon occurs when the engine’s spark plugs fail to ignite the fuel-air mixture in the cylinder at the right time.

In layman’s terms, the engine skips a beat, leading to decreased performance and reduced fuel efficiency.

A faulty spark plug, poor quality fuel, dirt or debris in the fuel system, or mechanical issues like a worn-out piston or valve can cause the issue.

To diagnose a misfire, look out for reduced engine power, rough idling, excessive vibrations, poor fuel economy, and the “Check Engine” light turning on.

If your Harley Davidson is misfiring, it’s recommended to consult with a qualified mechanic or a Harley Davidson dealership.

14. Engine Seizure

This issue arises when the engine’s moving parts, such as pistons inside the cylinders, are prevented from moving freely.

This can be caused by several reasons, such as inadequate lubrication, overheating, or the introduction of a foreign object into the cylinder.

When there’s a lack of proper lubrication, the friction between the moving parts increases, producing excessive heat, which leads to the components welding together, causing the engine to seize.

Overheating can also result from a faulty cooling system or prolonged high-speed rides without sufficient engine cooling.

Foreign objects in the cylinder can also instantly halt the piston movement, leading to a sudden seizure.

In order to address an issue, check if it’s a lubrication issue, ensure the use of high-quality oil, and regularly check oil levels.

Overheating can be prevented by maintaining the cooling system and avoiding long, high-speed rides without breaks.

A regular and thorough engine check can help in the early detection of any foreign objects in the cylinder.

Tonmoy, the brains behind the influential motorcycle-focused website, TwoWheller.com, is a dedicated and passionate advocate for biking culture. Born and raised in a family of motorcycle enthusiasts, his love for two-wheeled transportation was ignited at an early age. His commitment to providing in-depth reviews and helpful tips for riders has established him as a respected figure in the motorcycle community.